Tea Extraction

Tea Extraction System Introduction

1. Kneader Type

The system is suitable for various kind of tea including black tea, green tea, Chinese tea, Barley tea… etc.

2. Vertical Pressure Type

The system is suitable for various kind of tea including black tea, green tea, Chinese tea, Barley tea, and coffee extraction.

3. Traditional Type

The system is suitable for various kind of tea including black tea, green tea, Chinese tea, Barley tea… etc.

Specification

| Disposing Capability | 6000L/H (Max) |

|---|---|

| Time Range | 5min~30min |

| Temperature Range | 60~100˚C |

Remark: The capacity will be varied depending on different tea leaves used and the specific requirement by the customer.

For more information and further details, please contact with TBC sales representative in your city.

Features

The most favorable feature of this system is:

All procedures from tea-measuring, affusion, continuous extraction, tea-recycling to tea dust discharging are finished automatically and continuously. It can do recycling manufacture, therefore the production capacity is greatly improved.

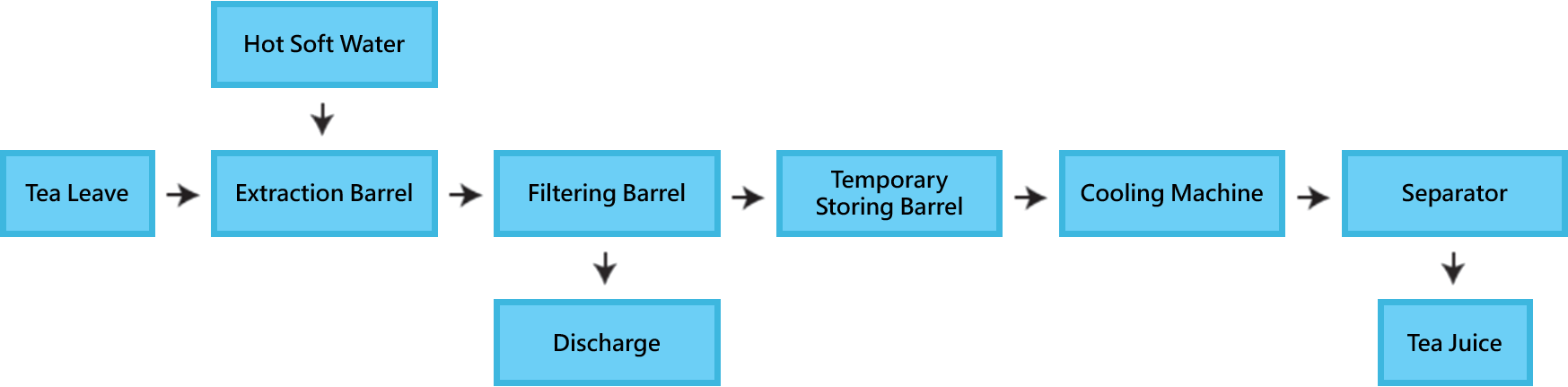

Flow Chart

The advantages of this system are mainly shown in the following five aspects:

Better Product Quality

Close production system has not only effectively reserved the flavor, but also prevented the products from catalytic oxidation which can make the tea juice bitter and deposited. This feature can be greatly shown in the production of sensitive green tea products. In contrast with the open tea extraction system, the close one has greatly improved the security and sanitation of the product, reduced the pollution from the outside as well. On contrary, without these advantages, the traditional open tea extraction system waste a lot of resources. In addition, the continuous extract design is introduced in this system, thus enhanced enterprise's producing energy greatly. This continual single track way can get the same volume with fewer teas. And according to the production data comparison, the tea polyphenol and the caffeine content outdoes 15% and 60% equally compared to the traditional way, thus the quality and stability has been greatly enhanced and reduced the cost as well.

Energy-Saving

Furthermore, this system minimizes the heat loss because the close container can keep the extraction temperature well. Through plate heat type exchanger, the heat tea extraction liquid firstly do heat exchange with production water to recycle heat recycle. During this process, water heat up to 50⊥, then enter into dash pot to prepare next batch production, which greatly save the steam and cooling water consumption and avoid workroom pollution caused by steam dissipation.

Easy Operation

Auto-operation is easily used and safe with high accuracy. The only manual process in this whole system is putting the tea into extraction pot; others are all automatically finished by distant-controlled valve. To make the tea with special flavor, the operator selects the pre-set memory formality in PLC as per different products. And this also can be realized by adjusting the temperature、sluggish air and time on touch screen. By this way, the mistake made by operator is greatly reduced.

Safe & Labor-Saving

High temperature work as tea dust disposing…etc are all automatically operated by distant-controlled valve due to the hot water affusion which avoid the accident. In comparison with the traditional open and nacelle semi-auto machine, continual extraction is safer and economic.

Easy Cleaning

After tea extraction, tea dust will be discharged through auto-valve at the bottom, and then feed out through conveyor. Therefore has relieved the before messy and dirty phenomenon, maintained the working place clean and neat.