The conveyor system is including air conveyor, top chain conveyor, roller conveyor, belt conveyor (Including bottle clip, can clip, carton clip and vertical lifter) , Slope conveyor and Vertical conveyor. Depend on transport target to design (Speed control, Centralized or decentralized…etc).

Applicable scope

Could be widely used in food, brewery, chemical and dairy products.

Air conveyor

Applicable scope

Air conveyor is a very clean way to carry empty PET bottles between blowing machine and filler.

Features

- bottles are handled by the neck, and motioned by an air stream generate by fans.

- The dynamic accumulation avoids the blowing machine to be stopped in case of a minor problem on the filling unit.

- Air conveyor in stainless steel 304.

- Neck guide made in food grade polyurethane

- Support by stainless steel foot.

Top chain conveyor

Applicable scope

The machine is used in conveying the empty or filled bottles. It is the main purpose to link various machines together with each other, including filling machine, tunnel cooler, bottle dryer, sleeve labelling machine, printer and wrap around caser.

Features

Design principle

- Designing according to the different efficiency and the bottle shape.

- Realizing the smoothly velocity changeover of the top chain though the suitable drive ratio, and the non-pressure conveying to avoid the fall, jam and extrusion of the bottle in the process of conveying.

- Reducer adjusting the velocity by inverter, controlled by PLC, the whole line running status is monitored by the approach switch and photoelectric switch, it can automatically control the velocity of every segment of the top chain real-time to avoid the shut down of the machine because of the jam or extrusion of the bottle.

Structure

- The framework of the main body adopt by SUS304

- The lubricating water spray system

- The water tank, collecting water tank and the drainage pipe

- Stainless steel cable tray

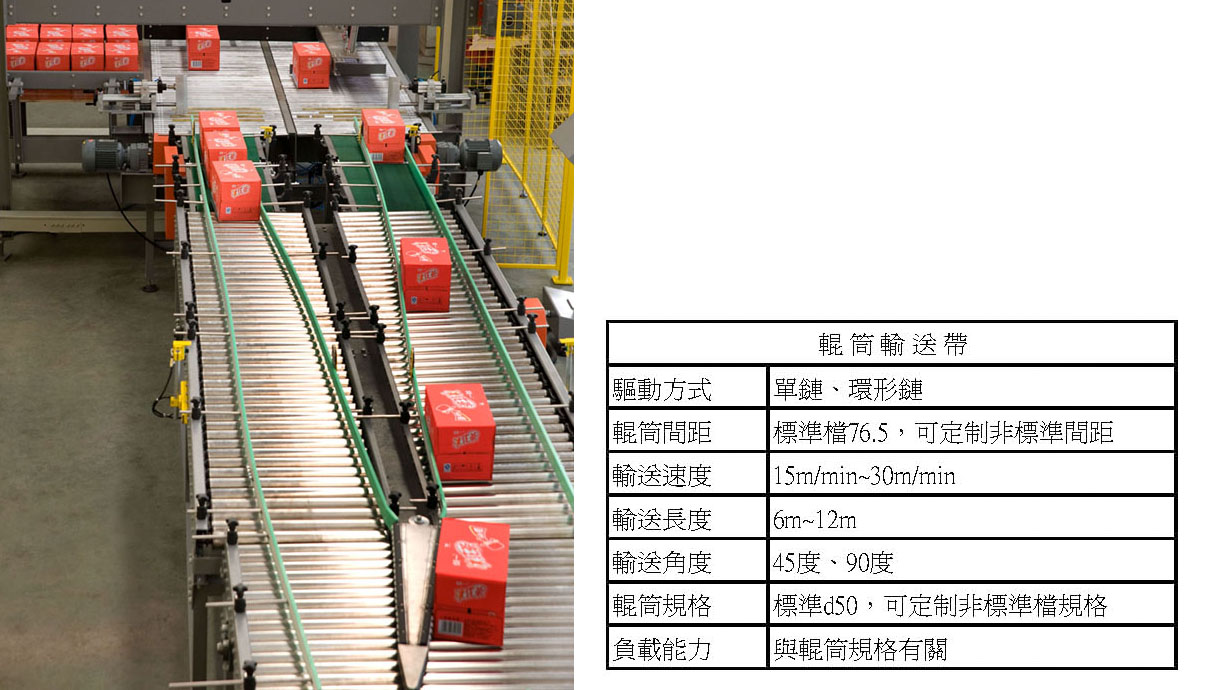

Roller conveyor

Applicable scope

Suitable for conveying paper carton, crater and drum, it will convey the finished product quickly to pile onto palletizer so that it will reduce the carrying time by manual work and enhance the efficiency.

Features

| Conveying method |

Roller conveying |

| Mainly type including |

Accumulate type/ Free roller/ Curve roller |

| Control mode |

Electrical cabinet control (powered roller conveyor)/ Free mode (non-motivated

roller conveyor). |

- the unitary design (according to the requirements of customers), including the length of conveyor belt, the width of conveyor belt side, and fixed the method, and the design of mounting method.

- Easy conveying principle of the complete assembly of the machine, and simple mounting in the field, and flexible shape.

- Electrical cabinet control mode, totally running in the automatically mode, and also operated by separately manual mode, easy to learn how to be operated in the field; you can select the different conveying velocity according to the different situation of the field.

- Easy and simple to maintain the conveyor.

Belt conveyor

Applicable scope

Belt conveyor belt (can be divided into Bottle clamp, Can clamp, Box clamp and lifting belt conveyor belt). This equipment is suitable for cartons, plastic boxes, bags, fruit sorting, beverage empty bottle conveying, etc.

The use of this equipment can reduce pollution during the transportation of products, reduce labor costs, and improve work efficiency.

Features

| Transport way |

By belt |

| Control |

By electric control box |

- Overall design (designed according to the needs of customers), including the length of the conveyor belt, the width of the conveyor surface, and the design of the fixing method and the installation way.

- The transportation principle of the whole set of equipment is simple, the on-site installation is simple, and the form is flexible.

- Controlled by the electric box, it can be operated in an overall automatic mode, or it can be operated manually. On-site operation is simple and easy to learn, and different conveying speeds can be selected according to different conditions on site.

- The conveying surface in contact with the product is a food-grade conveyor belt, and the side panels, body panels, and pallets are all food-grade stainless steel, and the materials are in full compliance with GMP specification.

- Equipment maintenance is simple and easy, belt adjustment is simple and fast.

- Easy cleaning of belt surface.

Slope conveyor

Applicable scope

This equipment is suitable for inclined surface conveying of finished products. The width, slope height and length can be customized according to customer requirements.

Features

| Transport way |

By not slid top chain. |

| Control |

By electric control box |

- Overall design (designed according to the needs of customers), including the length of the conveyor belt, the width of the conveyor surface, and the design of the fixing method and the installation way.

- The transportation principle of the whole set of equipment is simple, the on-site installation is simple, and the form is flexible.

- Controlled by the electric box, it can be operated in an overall automatic mode, or it can be operated manually. On-site operation is simple and easy to learn, and different conveying speeds can be selected according to different conditions on site.

- Equipment maintenance is simple and easy, belt adjustment is simple and fast.

Vertical conveyor

Applicable scope

This equipment is suitable for vertical conveying of empty bottles, finished products and packaging materials.

Features

| Transport way |

Continuous/Reciprocating |

| Control |

By PLC |

- Overall design (designed according to the needs of customers), including the length of the conveyor belt, the width of the conveyor surface, and the design of the fixing method and the installation way.

- The transportation principle of the whole set of equipment is simple, the on-site installation is simple, and the form is flexible.

- Controlled by the electric box, it can be operated in an overall automatic mode, or it can be operated manually. On-site operation is simple and easy to learn, and different conveying speeds can be selected according to different conditions on site.

- Equipment maintenance is simple and easy, belt adjustment is simple and fast.