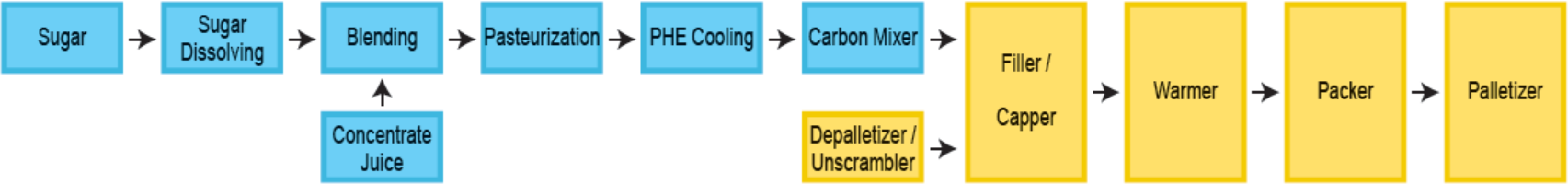

Soft drink production line

Suitable product to be treated:

Carbonated soft drink

Suitable container to be treated:

PET or CAN

Available capacity

18,000bph ~ 36,000bph (based on 0.5L container)

Production line feature

- The line is designed and constructed by TBC at a turn- key basis.

- Client contacts with one window only from the contract signature, normal production and after service.

- Each of equipment designed according to Food sanitary standard, which guarantees the hygiene of the products.

- Most optimized and efficient design according to customer's requirements.

- Whole system is designed with automatic control system; from production in the beginning till the finish of production with auto CIP system, the system is established and program memorized for operate automatically.

- Human machine interface with touch up operator panel.

- Semi- auto design is available based on requirement.

The supply of turn-key system is inclusive of liquid process system and packaging system.

Liquid process system

- Sugar dissolving and filtration system

- Syrup pasteurization system

- Blending system

- CIP system

Packaging system

- Unscrambler or depalletizer

- Rinser / Filler / Capper monoblock

- Cap pasteurization by UV or chlorine water

- Tunnel warmer

- OPP roll fed labeling or sleeve labeling

- Inkjet coder

- Packing machine( wrap around caser or shrink wrapper)

- Palletizer

- Various conveyor system, including air conveyor, gable top chain conveyor, roller chain, plastic conveyor