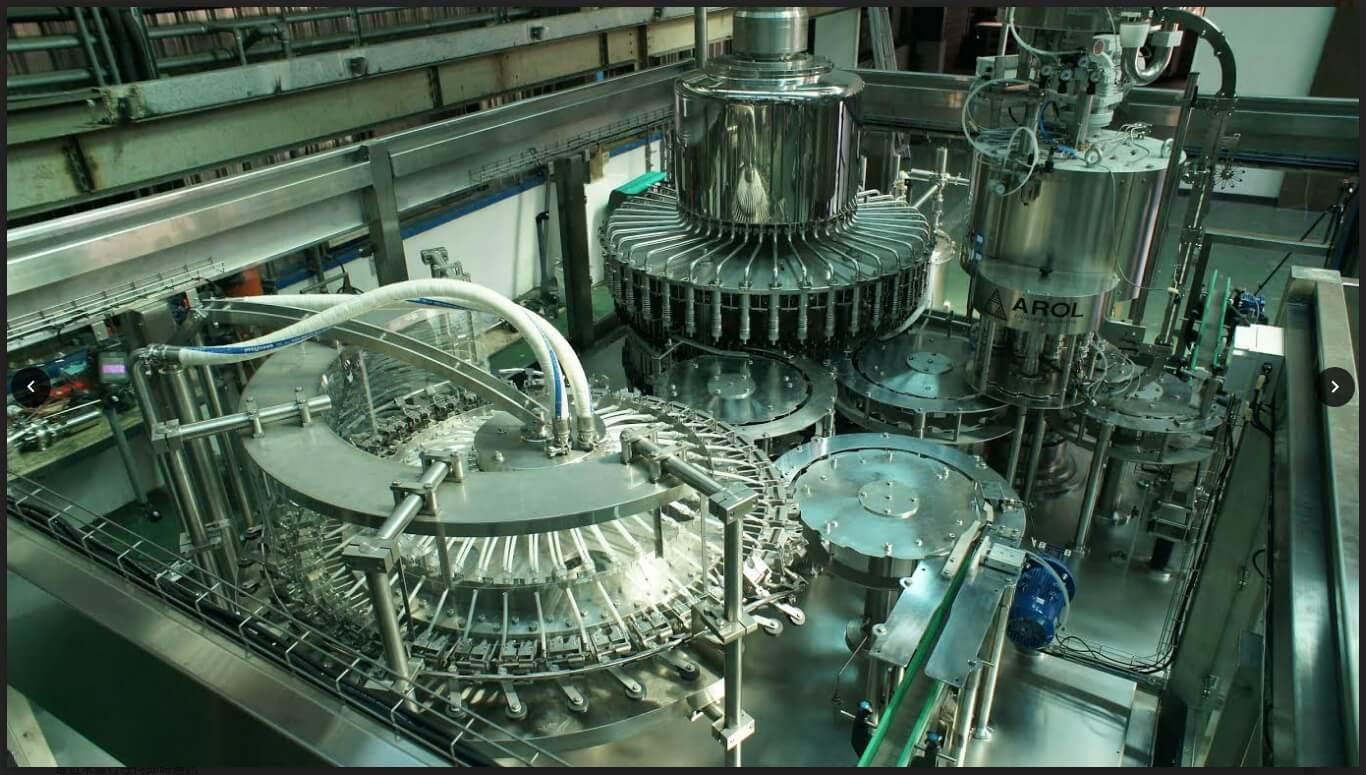

Rinser/ Filler/ Capper Monobloc

TBC fillers are designed to meet different application including hot fill and cold fill, the product will be covering from juice, green tea, black tea product filling at around 90℃, and ambient temperature filling for all kind of still product.

The filler is manufactured with Rinsing / Filling / Capping in a mono block design.

The filler is manufactured with the design of easy operation and access for machine maintenance.

Specifications

| Model | MARS series filler |

|---|---|

| Application | fruit juice, tea, hot filling product |

| Speed Range | from 12,000 to 30,000 bottles per hour |

| Bottle Size | 500ml~2L PET bottle |

| Cap Size | suitable for plastic caps from 25mm to 38mm |

| Filling Temperature | 85 to 92 ℃ |

Machine Descriptions

- Neck support for PET bottle handling, easy changeover when change bottle sizes required.

- Spray stages at rinsing area

- Stainless steel star wheels and guide rails

- Rinser carousel and filler carousel with gear driven for steady and long life operation; driven with frequency inverter for different speed control

- Jack lifter design to raise bottles to open the filling valve

- Ultra clean design by HEPA filtration system for filling and capping area depending on application and requirement

- Capping turret including sorter and pick and Place cap feeding system, ZALKIN or AROL turret will be available depending on requirement.

- Equipped with auto PLC program control with ; available by Siemens; Mitsubishi or others

- Automatic lubrication system

- Man Machine Interface(MHI) Touch screen operation panel

- Stainless steel electrical panel