Hot filling

Suitable applied product

Fruit Juice, Black Tea, Green tea, Energy drink

Suitable container to be treated

PET or CAN

Available capacity

18,000bph ~ 36,000bph (based on 0.5L container)

Production line features

- The line is designed and constructed by TBC at a turn- key basis. Client contacts with one window only from the contract signature, line production and after service.

- Each of equipment designed according to Food sanitary standard, which guarantees the hygiene of the products.

- Most optimized and efficient design according to customer's requirements.

- Whole system is designed with automatic control system( semi-auto as option); from production starting till ending production with auto CIP system, the system is established and program memorized for operate automatically.

- Human Machine Interface with Touch Up Operator Screen.

- Semi-auto design is available based on requirement.

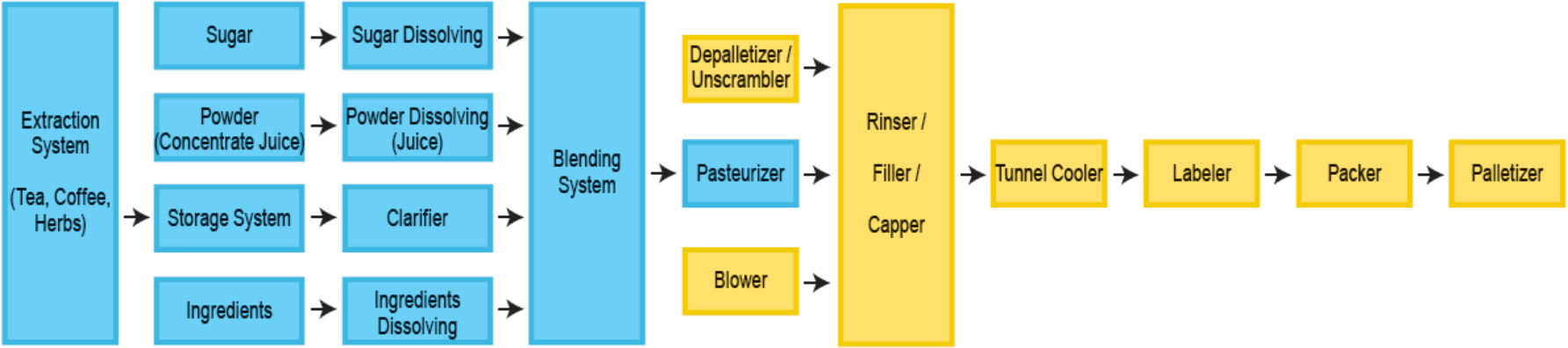

The supply of turn-key system is inclusive of Liquid process system, which covering from the equipment supply as below

- Tea extraction system

- Tea clarifier

- Sugar dissolving system

- Blending system

- UHT system

- Homogenizer

- CIP system

Packaging system: which covering the equipment supply as below

- Unscrambler or Depalletizer

- Rinser/Filler/Capper monoblock

- Cap pasteurization by UV or Chlorine water

- Tunnel cooler, bottle dryer

- Sleeve labeling

- Inkjet coder

- Packing machine( wrap around or shrink wrapper)

- Palletizer

- Various conveyor system, including Air Conveyor, gable top chain conveyor, roller chain, plastic conveyor

Flow Chart